7 Professional Techniques for Effective Paint Correction

Paint correction is more than just a wash and wax; it’s a detailed process of restoring and rejuvenating the paintwork of a vehicle, primarily by eliminating surface imperfections like scratches, swirl marks, and oxidation. If you’re looking to achieve a flawless finish, then understanding and applying professional techniques is key. Let’s delve into some expert methods that can help you bring out the best in your vehicle’s paintwork.

1. Understanding Paint Defects and Their Causes

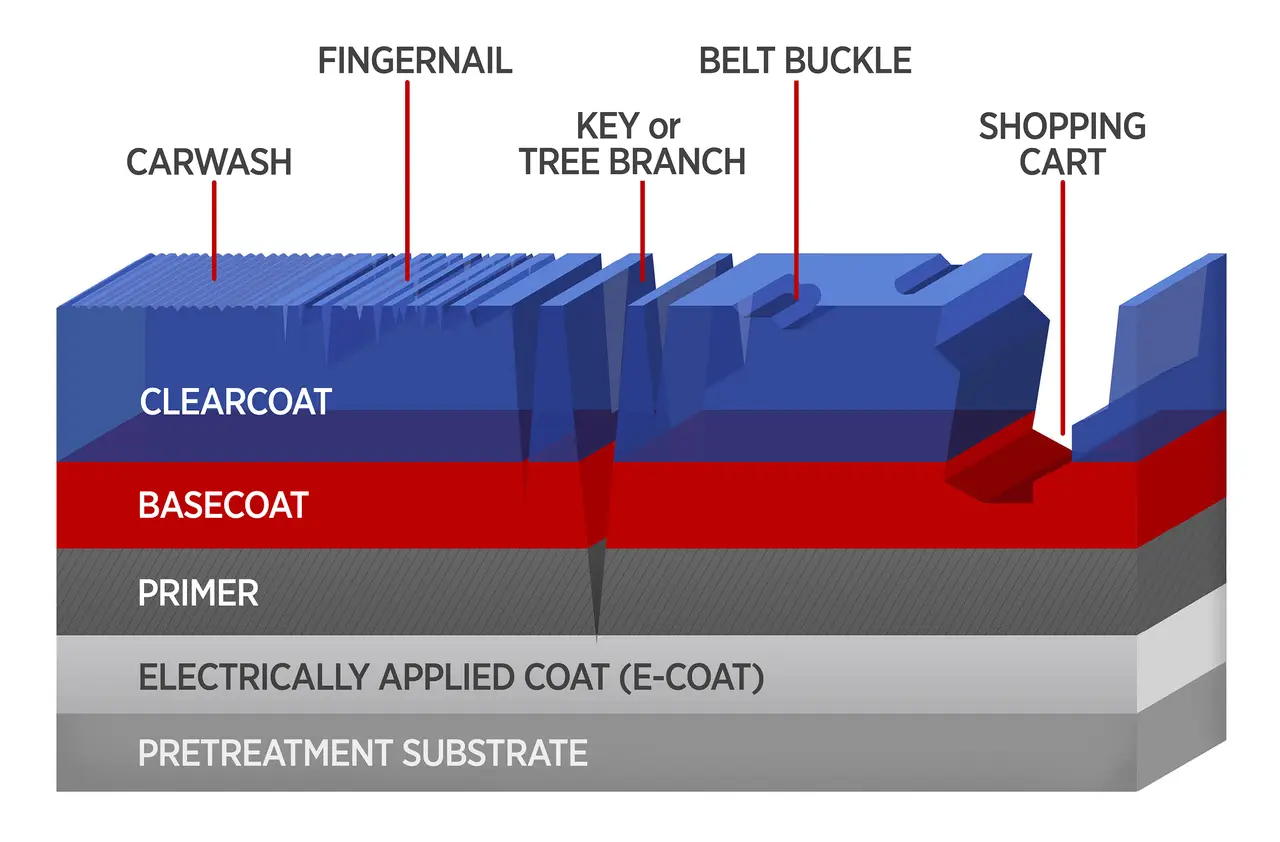

Before diving into correction techniques, it’s essential to identify and understand the various paint defects your vehicle might be suffering from, such as scratches, water spots, and oxidation. Recognizing the cause of these issues will help in choosing the right treatment. For instance, scratches often occur due to improper washing techniques or accidental brushes against hard surfaces, while oxidation is generally a result of prolonged exposure to harsh environmental elements.

Swirl marks are another common defect, usually caused by circular washing or buffing motions. Awareness is key; understanding that each imperfection tells a story about your vehicle’s history can significantly impact your approach to correction. Taking the time to examine these defects closely will allow you to tailor your correction methods, enhancing efficiency and outcomes.

2. Choosing the Right Polishing Compound

Not all polishing compounds are created equal. Selecting the appropriate compound is crucial for effective paint correction. Consider the level of abrasiveness needed for the specific defects you are targeting to achieve optimal results. For deeper scratches, a more abrasive compound might be necessary, whereas lighter defects can often be addressed with a milder option.

It’s also vital to consider the compound’s chemical makeup. Some products are designed to work better with specific paint types or colors. A general rule of thumb is to start with the least aggressive compound and only move to harsher materials if the desired result isn’t achieved. This ensures that you preserve as much of the original paintwork as possible while achieving a flawless finish.

3. Using the Dual Action Polisher

One of the most popular tools for paint correction is the dual action polisher. This tool helps to evenly distribute polishing compounds, reducing the risk of paint damage. Learn how to master its use for a smooth and even finish. The dual action aspect refers to its orbital motion, which mimics hand-polishing movements, making it user-friendly even for beginners.

When using a dual action polisher, it’s crucial to maintain a consistent speed and pressure to avoid creating new defects such as holograms or buffer trails. The polisher works by generating heat through friction, which is necessary to break down the polish and allow it to work effectively. However, too much heat can damage the paint, so it’s a fine balance between achieving results and preserving the integrity of the surface.

4. Mastering the Technique of Hand Buffing

While machines are effective, there are areas where hand buffing shines. This technique allows for precision in hard-to-reach spots and can be gentler on the vehicle’s surface. Perfecting this method can greatly enhance your correction results. Hand buffing involves using soft applicator pads and a good quality polish to work on small areas with controlled movements.

A significant advantage of hand buffing is the ability to feel the paintwork as you go, allowing immediate feedback on your progress and preventing over-polishing. However, it requires patience and attention to detail, as it’s easier to miss spots without the overlapping action that mechanical polishers provide. For those troublesome areas, tackling them with a careful hand can make all the difference in achieving a seamless finish.

5. The Importance of Paint Thickness Measurement

Thorough paint correction requires knowledge of how much clear coat you can safely remove. Measuring paint thickness ensures you don’t over-polish, preserving the life of the vehicle’s exterior. A digital thickness gauge can provide accurate readings, identifying variations across different sections of the vehicle.

Knowing your limits is crucial, as the clear coat is finite and integral to the car’s overall protection. Over-polishing can lead to irreversible damage, exposing the paint to environmental hazards and diminishing shine. By regularly measuring paint thickness throughout the process, you maintain a safeguard against inadvertently reducing the clear coat below recommended levels, thus ensuring longevity and continued vibrance of the vehicle’s appearance.

6. Applying a Protective Ceramic Coating

Once the paint is corrected, applying a ceramic coating adds a layer of protection that enhances shine and guards against future damage. This step is crucial in maintaining the hard work put into paint correction. Ceramic coatings offer a semi-permanent bond with the paint, providing a hydrophobic surface that repels water and contaminants.

Application of ceramic coating requires a clean and dry surface following paint correction; any remaining residue or oils can affect the coating’s ability to adhere properly. It’s important to follow the manufacturer’s instructions for curing times to ensure maximum durability. The transformational effect of a ceramic coating is often seen immediately, with a notably smoother finish and increased gloss, protecting your investment and significantly reducing maintenance time and effort.

7. Regular Maintenance for Lasting Results

Post-correction care is vital for keeping the paint in pristine condition. Regularly washing and applying appropriate products will prolong the effects of your paint correction, keeping your car looking showroom-ready for longer. Utilize microfiber towels to avoid inadvertently introducing new scratches during washing, and employ the two-bucket wash method to minimize contamination.

In addition to washing, consider adding a routine application of a quick detailer or spray wax, especially if the vehicle is exposed to harsh environmental conditions. These practices create an additional protective layer over the ceramic coating and enhance the paint’s gloss between full washes. By focusing on continuous maintenance, you ensure that your meticulous efforts in paint correction remain visible and viable over the long term.

Latest Posts

9 Surprising Benefits of Regular Car Detailing in Winston Salem

Why Is Paint Correction Important for Vehicle Maintenance?

How Long Does Ceramic Coating Last on Cars in High Point, NC?